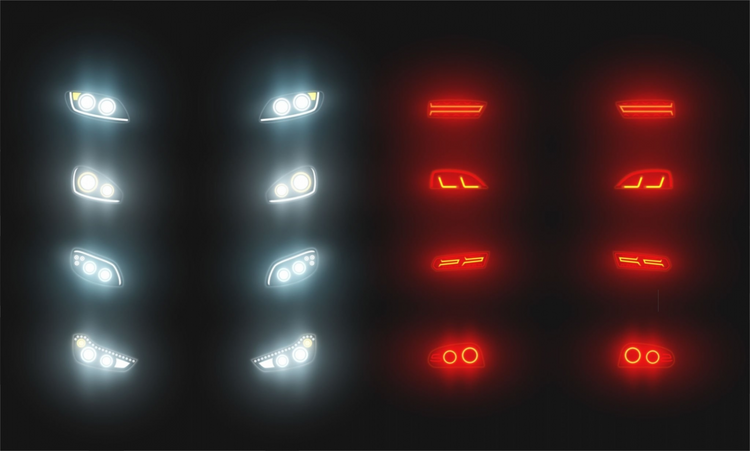

Car headlights, as the "eyes" of a car, are not only aesthetically pleasing but also essential for road illumination, enhancing visibility, and ensuring the safety of the vehicle. However, car headlights often encounter issues such as water ingress and fogging, which not only affect the lifespan of the headlights but also greatly diminish their illumination, consequently compromising driving safety. While water ingress is considered a quality issue that can be prevented and should not occur, fogging, on the other hand, is a natural phenomenon. This article primarily focuses on fogging in car headlights, explaining its mechanism and proposing optimized solutions.

1、Mechanism of Headlight Fogging

Headlight fogging is the result of water vapor condensing inside the headlights, transforming into a liquid or a mixture of liquid and gas under specific conditions. Condensation of liquid water from moist air can occur under two conditions: at a constant temperature or at a constant pressure. Most headlights nowadays have a semi-sealed structure with ventilation openings that facilitate the exchange of air between the inside and outside, ensuring equal pressures. Therefore, condensation of water vapor inside the headlights primarily occurs under constant pressure. When the headlights are turned on, the internal moist air is heated, leading to convection and radiation. When the convective moist air comes into contact with the cooler area of the headlight lens, fogging occurs on the surface of the lens. Additionally, when the headlights are turned off, the temperature of the headlight lens decreases faster than the internal temperature. When the temperature drops below the saturation temperature of the moist air, fogging also occurs in the headlights.

Understanding Headlight Fogging

Headlight fogging is a normal physical phenomenon that cannot be completely avoided. What we can do is minimize fogging under certain conditions without compromising road illumination, safety, and aesthetics.

Based on an understanding of the mechanism of water vapor condensation and the structure of car headlights, we can deduce that three conditions are necessary for headlight fogging: dew point temperature, condensation conditions, and theoretical models.

2、Solutions to Headlight Fogging

The design of car headlights faces several challenges related to fogging:

- Multiple types of light sources are used, leading to a mix of different light sources.

- The structure of headlights is becoming more compact, hindering airflow circulation.

- Headlight designs are becoming more diverse, with increased decorative rings.

- Customers have higher demands for the appearance of the products.

3、Design Optimization Solutions for Headlight Fogging

The shape and internal structure of the lamp cavity affect the temperature distribution inside the headlights, while the design and number of ventilation openings influence the airflow distribution within the lamp body.

To meet the requirements for aesthetics and design, car headlights often have elongated areas where air circulation is difficult, leading to the accumulation of water vapor. These areas are usually located far from the light radiation region, resulting in low-temperature zones.

Currently, finite element analysis is used to simulate the temperature distribution inside the headlights, identify the location of the cold zones, and optimize the structural design of the headlights. By arranging the internal components properly and eliminating or reducing the low-temperature zones caused by radiation flow, the design of the reflector can be optimized to alter the distribution of light source radiation. The goal is to achieve a uniform temperature distribution inside the headlights, avoid large temperature differences, and introduce ventilation openings or breathable films in the low-temperature zones or nearby areas while meeting the light distribution requirements.

4、Process Optimization Solutions for Headlight Fogging

During the production process of car headlights, the impact of process performance on fogging cannot be overlooked. One of the reasons for headlight fogging is the presence of critical nuclei. The material of the headlight lens is usually plastic, which is non-wetting to water. Condensation occurs on the surface of the lens in the form of droplets, which is visible to users. To address this issue, a solution has been developed: applying a layer of low surface tension coating on the inner surface of the headlight lens. This coating modifies the surface properties inside the reflector. With hydrophilic molecules aligned on the surface of the reflector, the surface tension matches that of water, resulting in a change in the condensation mode to a film-like condensation. This solution doesn't affect the appearance of the headlights and is not visible to users, effectively eliminating the condensation nuclei.

The main steps of this process are as follows:

4.1 Use an electrostatic dust removal gun to remove dust from the reflector to be coated.

4.2 Apply the coating using an automatic spraying device.

4.3 Place the coated reflector in a drying oven. It should be noted that this solution is not widely used due to its high cost. It is mainly implemented in luxury car models and serves as a final remedial measure.

5、Structural Optimization Solutions for Headlight Fogging

Based on the analysis of the fogging mechanism in car headlights, the third reason for headlight fogging is the presence of sufficient water vapor inside the headlights. If the humidity inside the headlights can be reduced as much as possible, it can help prevent fogging.To decrease the internal humidity of the headlights, common measures include enhancing the sealing performance of the components and improving the ventilation openings' ability to dissipate water vapor. Another approach is to add a desiccant inside the headlights to reduce internal humidity. However, this solution is effective in the short term and cannot guarantee long-term results.

6、Reasons for Eliminating Front Fog Light Configuration

There are two reasons to explain the decision to eliminate front fog lights:

a) Glare and Safety Concerns: Fog lights are designed to be used in foggy conditions. They have a shorter illumination distance and higher brightness. Incorrect use of fog lights can cause glare and impair the visibility of other road users, posing a safety hazard.

b) Better Cooling Efficiency: In recent years, many car models have been reducing the inclusion of front fog lights. One of the main reasons is to improve the cooling efficiency of the engine. The front air dam becomes a crucial area for air intake into the engine compartment, aiding in engine cooling. Automakers have prioritized utilizing the space previously occupied by front fog lights to allow external air to flow into the engine compartment, resulting in various cooling benefits.